Company

Solutions

Knowledge&Blog

Contact Us

Company Profile

Shanghai Qinghong Healthcare Products Co., Ltd.

Qinghong Medical- Your Trusted Global Health companion

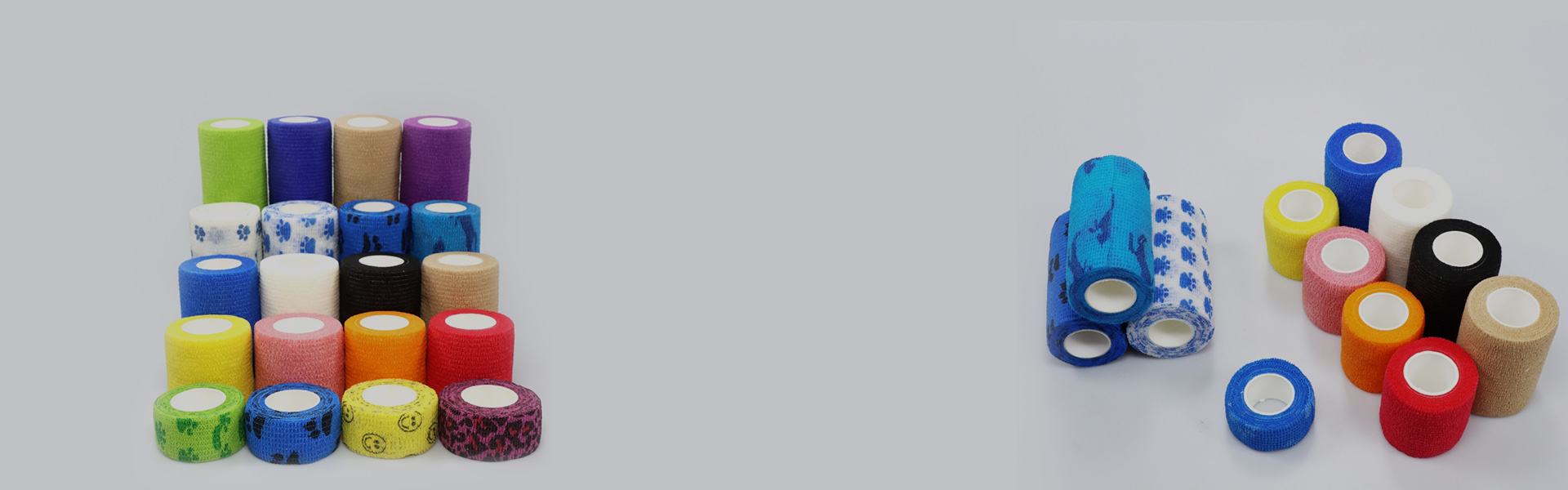

Shanghai Qinghong Healthcare Products Co., Ltd. is China Custom Printed Cohesive Bandage Manufacturers and Private Label Cohesive Bandage Suppliers, located in Jiading District, Shanghai, is a leading manufacturer and supplier specializing in high-quality elastic bandages and athletic tape. Jiangsu Qinghong Healthcare Products Co., Ltd., headquartered in Suqian City, Jiangsu Province, has been committed to providing high-quality self-adhesive bandages, kinesiology tape, and cotton athletic tape to customers worldwide since its establishment in 2018. Leveraging strong R&D capabilities, stringent quality control, and customer-centric service, we have become a trusted partner in the industry.

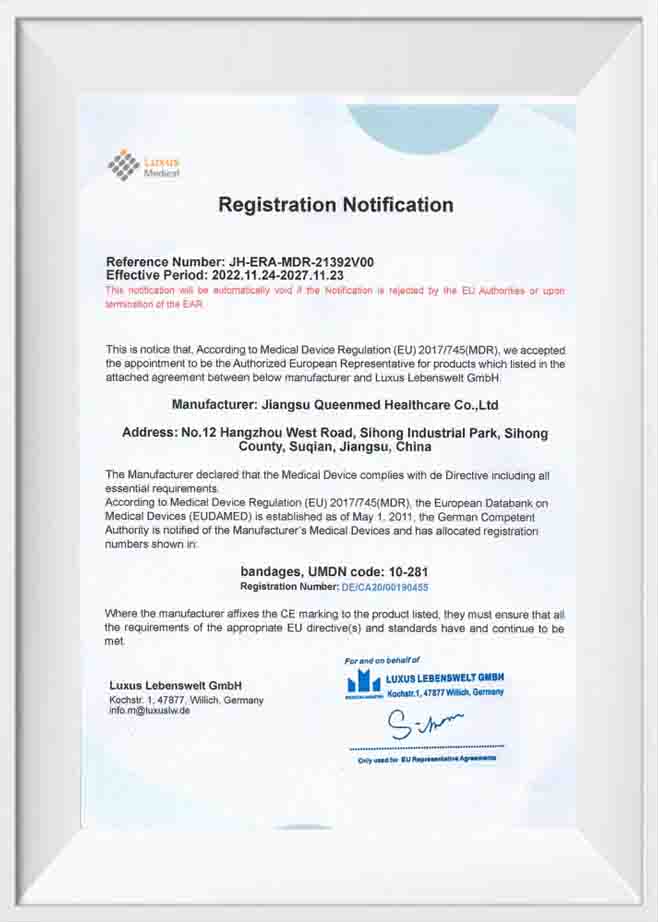

We operate a modern production base with comprehensive facilities and advanced technology, along with a dedicated R&D team and multilingual sales team. We control raw materials from the source and conduct comprehensive product testing using advanced testing equipment, ensuring our products are sold worldwide. We have obtained international certifications such as ISO13485, CE, and FDA.

We adhere to the principles of "Integrity, Win-Win, Innovation, and Pragmatism," continuously innovating, striving for excellence, and improving our quality management system to provide the highest-quality products and services to our domestic and international customers, meeting their ever-changing needs. We are confident that our expertise and dedication will satisfy you. We offer Cohesive Bandage for sale.

-

10,000m² 01

Factory Area

-

2018 02

Company Incorporation

-

200+03

Employees

-

100+04

Global Customers

NEWS

Latest articles

What are the common printing methods used on a printed cohesive bandage?

Private label printed cohesive bandage has become a vital product in healthcare, sports medicine, and veterinary applications due to its combination of functional support, skin-friendly properties, and visual customization. With growing demand for tailored branding and diverse designs, understanding the common printing methods used on a printed cohesive bandage is essential for manufacturers, buyers, and distributors.

Understanding private label printed cohesive bandage

A private label printed cohesive bandage is an elastic, self-adhering wrap that sticks to itself without adhesive, providing secure support for joints, muscles, and wounds. Its appeal lies not only in performance but also in its visual customization potential. Companies can create branded products or themed designs, catering to medical, sports, or promotional markets.

Key features of cohesive bandages

- Self-adhesive property: The bandage adheres to itself but not skin or hair, minimizing discomfort.

- Elasticity: Provides compressive support while allowing natural movement.

- Breathability: Ensures moisture control and prevents skin irritation.

- Custom printing compatibility: Enables logos, patterns, and designs without affecting performance.

Common printing methods for printed cohesive bandages

The printing process is crucial for private label cohesive bandage because it must maintain elasticity, cohesion, and skin safety while achieving visual clarity. Manufacturers typically use several proven methods, each with advantages and limitations.

1. Flexographic printing

Flexographic printing is widely used in the production of printed cohesive bandages due to its efficiency and ability to print on elastic substrates. This method uses flexible plates to transfer water-based or UV inks onto the bandage surface.

Advantages:

- High-speed production suitable for bulk orders

- Compatible with elastic materials without cracking

- Allows vibrant colors and multiple design options

Considerations:

- Plate preparation can be costly for small runs

- Ink formulation must be carefully selected to avoid affecting cohesion

2. Screen printing

Screen printing involves pressing ink through a fine mesh screen directly onto the bandage. It is especially useful for smaller batches and detailed designs.

Advantages:

- High ink opacity ensures bold and visible designs

- Effective for logos, symbols, or promotional graphics

- Relatively low setup cost for limited quantities

Considerations:

- Slower production speed than flexographic printing

- Requires precise alignment to prevent ink bleeding on elastic materials

3. Heat transfer printing

Heat transfer printing involves transferring pre-printed designs from a film or paper onto the cohesive bandage using heat and pressure.

Advantages:

- Allows full-color photographic designs

- Can produce complex patterns that are difficult with other methods

- Suitable for small to medium private label runs

Considerations:

- Requires careful control of temperature to prevent bandage distortion

- Adhesive layer for heat transfer must be compatible with bandage material

4. Digital printing

Digital printing directly applies ink using inkjet or similar technology. It is becoming increasingly popular in private label manufacturing due to flexibility and minimal setup.

Advantages:

- No need for physical plates or screens, reducing setup costs

- Ideal for small batches or personalized designs

- Supports intricate patterns and gradients

Considerations:

- Ink adhesion and durability must be tested for elastic substrates

- Slower throughput for high-volume orders

Technical requirements for printing on cohesive bandages

Printing on private label printed cohesive bandage is not solely about visual appeal. It must consider the bandage’s mechanical and chemical properties.

Material compatibility

Cohesive bandages are typically made of cotton, polyester, or non-woven elastic blends. Printing inks must:

- Flex with the bandage without cracking or peeling

- Be non-toxic and skin-safe

- Resist fading from sweat or moisture

Durability and performance

The printed design should withstand stretching, compression, and repeated use. Poorly selected inks or printing methods can compromise:

- Cohesion, affecting the bandage’s self-adhesive property

- Elasticity, leading to reduced compressive support

- Color fastness, causing fading during application or washing

Quality control

Reputable manufacturers implement strict quality control measures to ensure printing consistency. This includes:

- Testing ink adhesion and elasticity

- Evaluating stretch recovery after printing

- Verifying compliance with international standards such as ISO 13485, CE, and FDA

Customization options for private label cohesive bandages

Private label branding allows businesses to differentiate their products in the competitive market. Printing is central to this customization.

Logo and brand designs

Companies can place logos, brand names, or slogans directly on the bandage, enhancing brand recognition.

Patterns and colors

Printed cohesive bandages can feature a wide array of colors and patterns, such as camouflage, stripes, or themed graphics, without compromising functionality.

Packaging and labeling

In addition to the bandage itself, customization extends to packaging. This may include:

- Branded boxes or wraps

- Instructional or marketing labels

- Bulk packaging for professional use

Advantages of working with specialized manufacturers

Collaborating with a reliable manufacturer of private label printed cohesive bandage ensures high-quality output and efficient production.

Production capacity and R&D expertise

Leading manufacturers operate advanced production facilities equipped with automated machinery. A dedicated R&D team supports:

- Innovation in bandage material and ink formulations

- Development of new printing techniques for elasticity preservation

- Optimization of production processes to meet large-volume orders

Quality assurance and certifications

Manufacturers adhere to strict quality management systems, including:

- Raw material audits to ensure consistency

- In-house laboratory testing for performance and safety

- Compliance with ISO 13485, CE, and FDA standards, ensuring products meet international regulatory requirements

OEM/ODM support

Flexible customization services enable businesses to:

- Choose printing methods, designs, and colors

- Customize packaging and labeling

- Launch branded products without investing in manufacturing infrastructure

Comparison of printing methods for private label cohesive bandages

| Printing Method | Advantages | Considerations | Best For |

|---|---|---|---|

| Flexographic printing | High-speed, vibrant colors | Costly plates for small runs | Bulk orders |

| Screen printing | Bold designs, opaque ink | Slower, alignment critical | Logos and symbols |

| Heat transfer printing | Full-color complex designs | Temperature control needed | Medium-sized custom orders |

| Digital printing | Small batches, intricate patterns | Slower for high volume | Personalized or promotional use |

Market applications

Private label printed cohesive bandage serves multiple industries:

- Healthcare: Provides secure support for injured joints or muscles in hospitals and clinics.

- Sports and fitness: Used for athletic tape, pre-wrap, or therapeutic compression.

- Veterinary care: Offers animal-safe support without adhesives sticking to fur.

- Promotional and retail: Customized designs enhance brand visibility for sports teams, events, or corporate giveaways.

By choosing the appropriate printing method, businesses can ensure their private label cohesive bandage meets functional requirements while appealing to end users.

Conclusion

Understanding common printing methods used on a printed cohesive bandage is essential for businesses and buyers aiming to offer high-quality, visually appealing products. Each printing method—flexographic, screen, heat transfer, or digital—has specific advantages and limitations that influence elasticity, cohesion, and color durability.

Working with a reputable manufacturer ensures compliance with international standards, consistency in performance, and flexibility for customization. Private label printed cohesive bandage offers an excellent opportunity to enhance brand identity while delivering functional, reliable, and visually attractive bandages across healthcare, sports, and promotional markets.

By carefully considering material compatibility, printing techniques, and quality control, companies can develop products that meet both professional and consumer expectations, ensuring long-term market success.

English

English  русский

русский  Français

Français  Español

Español  عربى

عربى

ENG

ENG